Dispensing System Solvent Single Point Dispenser

Dispensing equipment in the application of synthetic leather industry, through actual test and verify by users, various performance can be qualified, can make the process like a production line, same as big dispensing system in production performances.

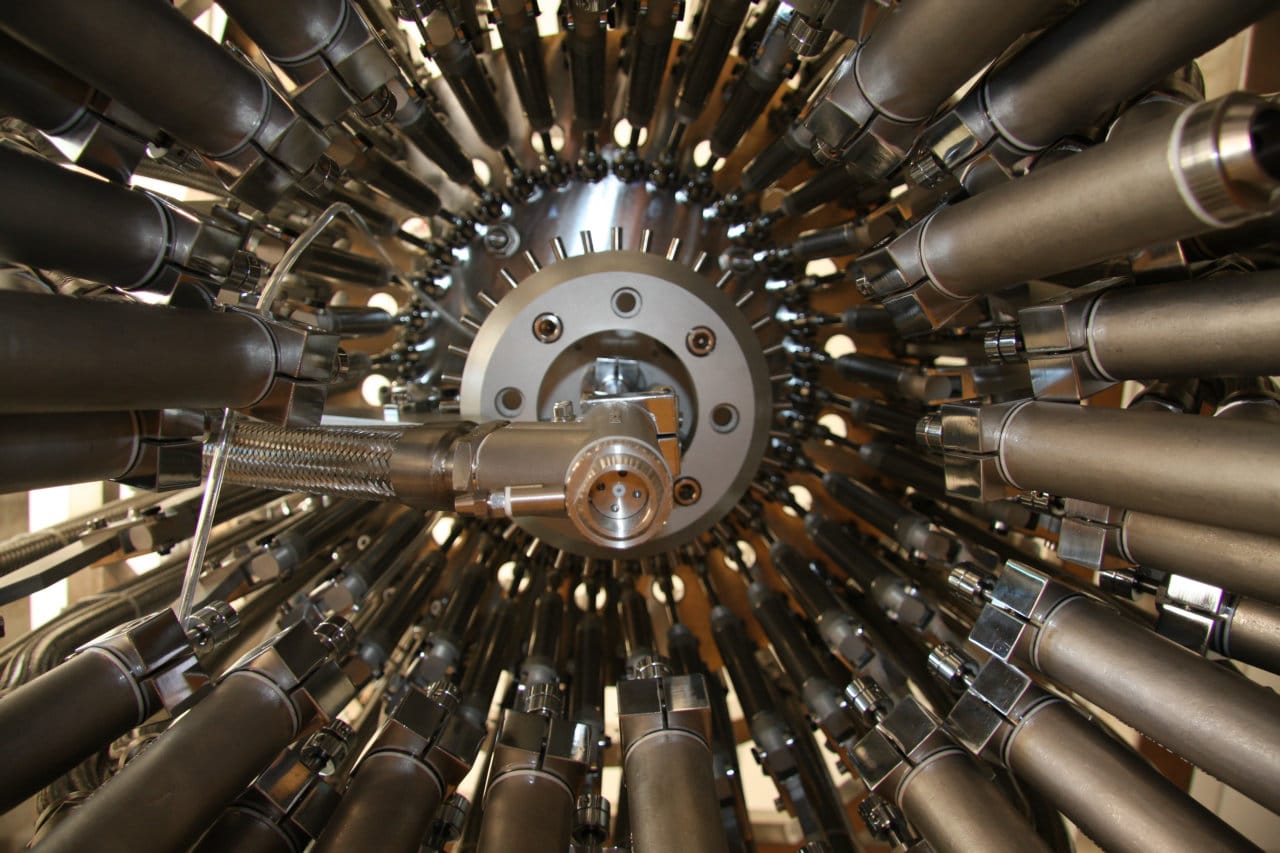

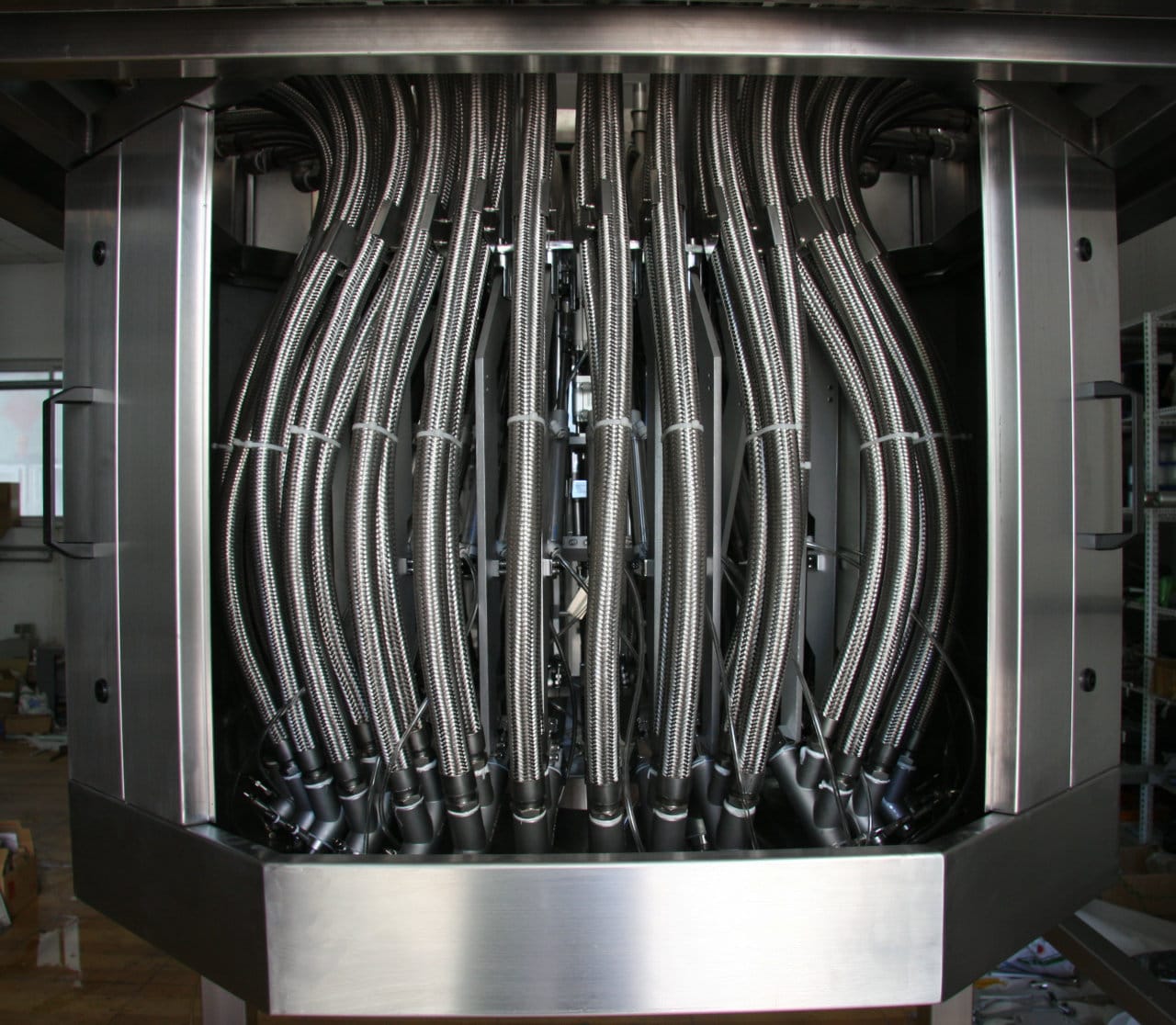

Valves are placed on swing arms or slide guide. When dispensing, the valve is moved to the central position and the flow of the valve is controlled by the opening unit. Valves can be operated at high, medium, low and drip speeds. This dispensing method can ensure that the material is dispensed into a very small container. The method are divided into swing type and push type.

Valve quantity: up to 60

Valve seal: free O-ring

Explosion proof type: Positive pressure explosion-proof

Ex grade: Zone 1 or Zone 2

Valve size: DN20-DN65

Pump size: DN15-DN65

Electronic scale: 7-1500kg

Accuracy: up to 0.1g

Container size: >250mm

Efficiency: 4-5min/20kg 8-10min/200kg 20-30min/1500kg

Diaphragm Pump

Specification: 1”

Models: 666120-344-c

Pump Type: Metallic Air Operated Double Diaphragm

Maximum Air Inlet Pressure: 120 psig (8.3 bar)

Maximum Material Inlet Pressure: 10 psig (0.69 bar)

Maximum Outlet Pressure: 120 psig (8.3 bar)

Maximum Flow Rate (flooded inlet): 35 gpm (133 lpm)