Lowest Price for Pharma Kitchen - Ink Dispensing System Pneumatic Semi-Automatic Mixer – Golden Color

Lowest Price for Pharma Kitchen - Ink Dispensing System Pneumatic Semi-Automatic Mixer – Golden Color Detail:

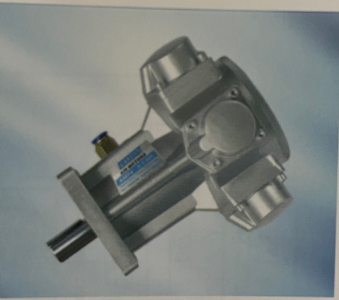

Piston pneumatic motor Mainly consists of: motor shell, connecting rod, crankshaft,piston and cylinder, valve, etc. Compressed air into the air with its core, with rotation by air, will be the core of compressed air into the surrounding air cylinder respectively,due to the expansion of compressed air in cylinder, so as to promote the piston and crankshaft connecting. when the piston is pushed “down dead spots”, with the core with air exhaust to first place. The expansion of the gas automatically from the exhaust duct cylinder valve directly after discharge. While the residual gas piston cylinder valve core with all the vent duct, corundum, through such reciprocating cycle can make the crankshaft constantly rotating. Its function mainly comes from the gas expanding power.

Above because the piston air motor has many characteristics, therefore it can be in damp, high temperature, high dust and other work under the harsh environment. In addition to be used in the mining machinery in drilling, drilling, loading equipment, such as motivation, shipbuilding, metallurgy, chemical industry, papermaking, etc are also widely used.

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Lowest Price for Pharma Kitchen - Ink Dispensing System Pneumatic Semi-Automatic Mixer – Golden Color , The product will supply to all over the world, such as: Eindhoven, USA, Rotterdam, Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.