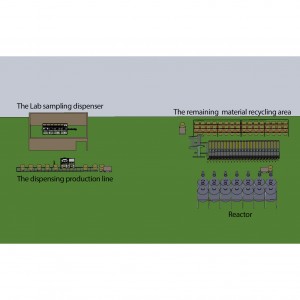

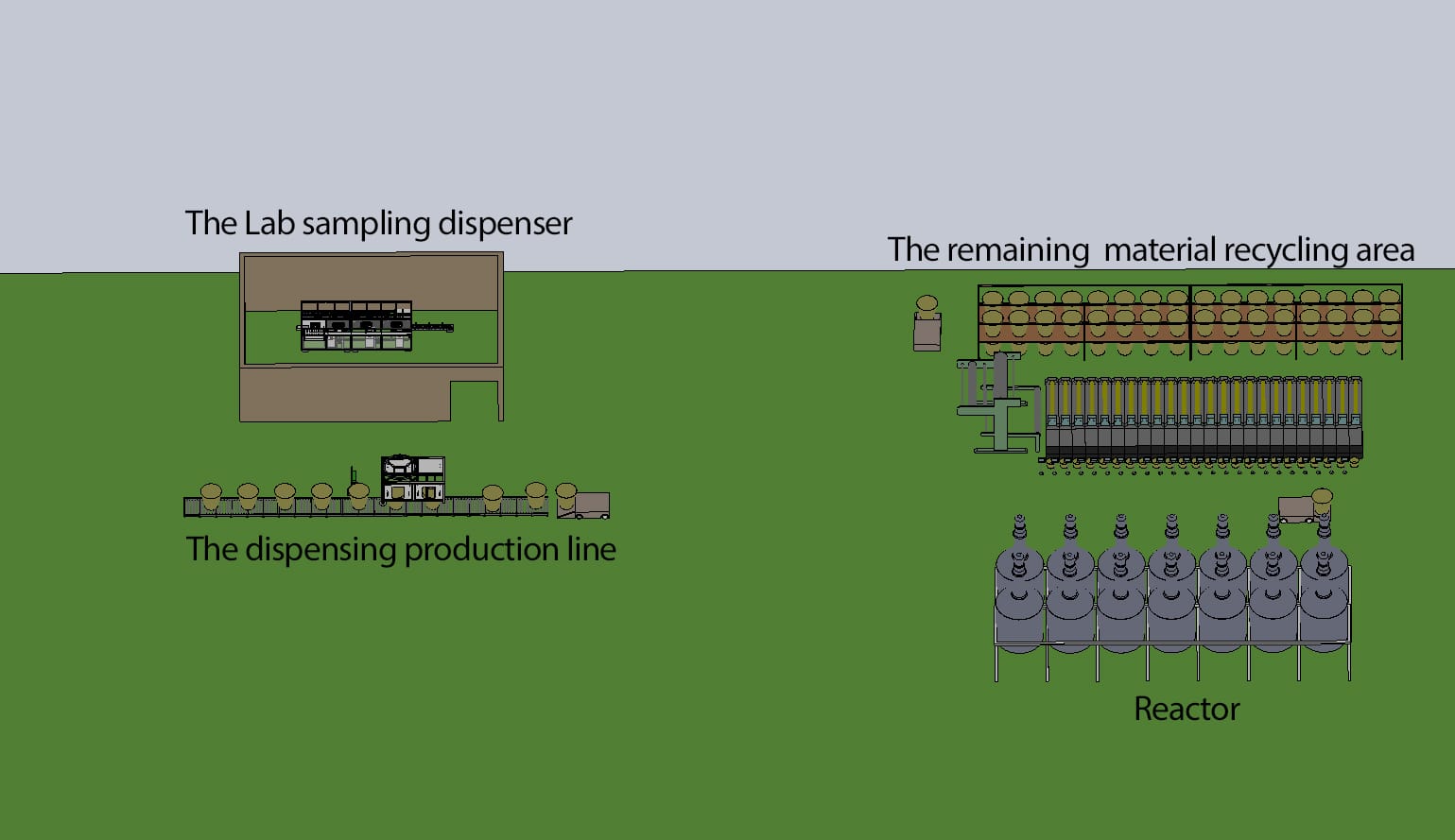

Dispensing System Laboratory Multi-Axis Mixer

Digital ingredients overall solution

● Customers receive samples through automatic sample making, sample confirmation after the formula automatically transferred to the process room;

● Process room input forecast production plan, software automatically generate batching quantity;

● Production plan is displayed at each reactor terminal;

● Operators select production plans;

● The software automatically generates the bar code according to the selected production plan and prints it automatically in the batching room;

● Batching room personnel are responsible for pasting the bar code on the empty barrel and scanning, automatic batching system according to the bar code

Dynamic ingredients;

● Feed personnel (or AGV car) is responsible for the bucket to the reactor to the designated location.

Golden Color Dispensing Software

Full Product Management

Full Inventory Management

Auto and manual dispense

Export to Excel file

Reuse Press returns

Cost Tracking

Multi-Lingual Operation

Built-in Pantone

Color quality control(spectrophotometer needed)

Support bar code reader, printer

Using the enterprise cloud platform (the formulation of database on the Internet) can

Implement multiple printing basis points of connection, headquarters can connect the

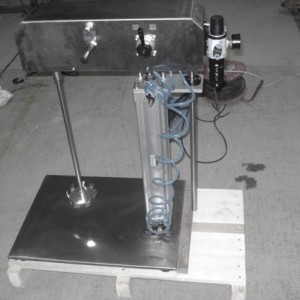

INDUCTION MOTORS

Output power(W): 25

Voltage(V): 3ph 380

Frequency(Hz): 50

Current(A): 0.106

Starting Torque(mN.m): 350

Rated Torque(mN.m): 200

Rated Speed(r/min): 1250