Chinese wholesale Pharma Dispensing System - Ink Dispensing System Solvent Single Point Dispenser – Golden Color

Chinese wholesale Pharma Dispensing System - Ink Dispensing System Solvent Single Point Dispenser – Golden Color Detail:

Dispensing equipment in the application of synthetic leather industry, through actual test and verify by users, various performance can be qualified, can make the process like a production line, same as big dispensing system in production performances.

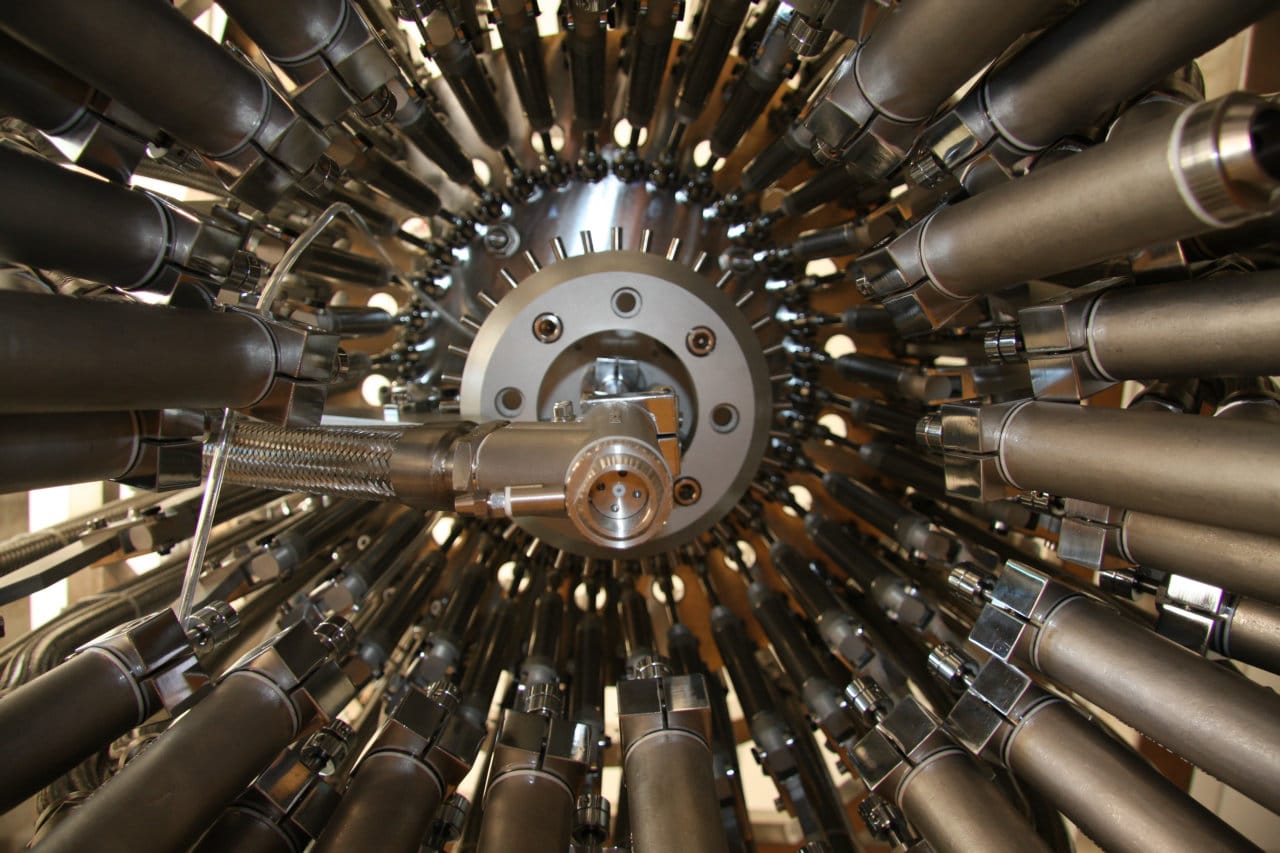

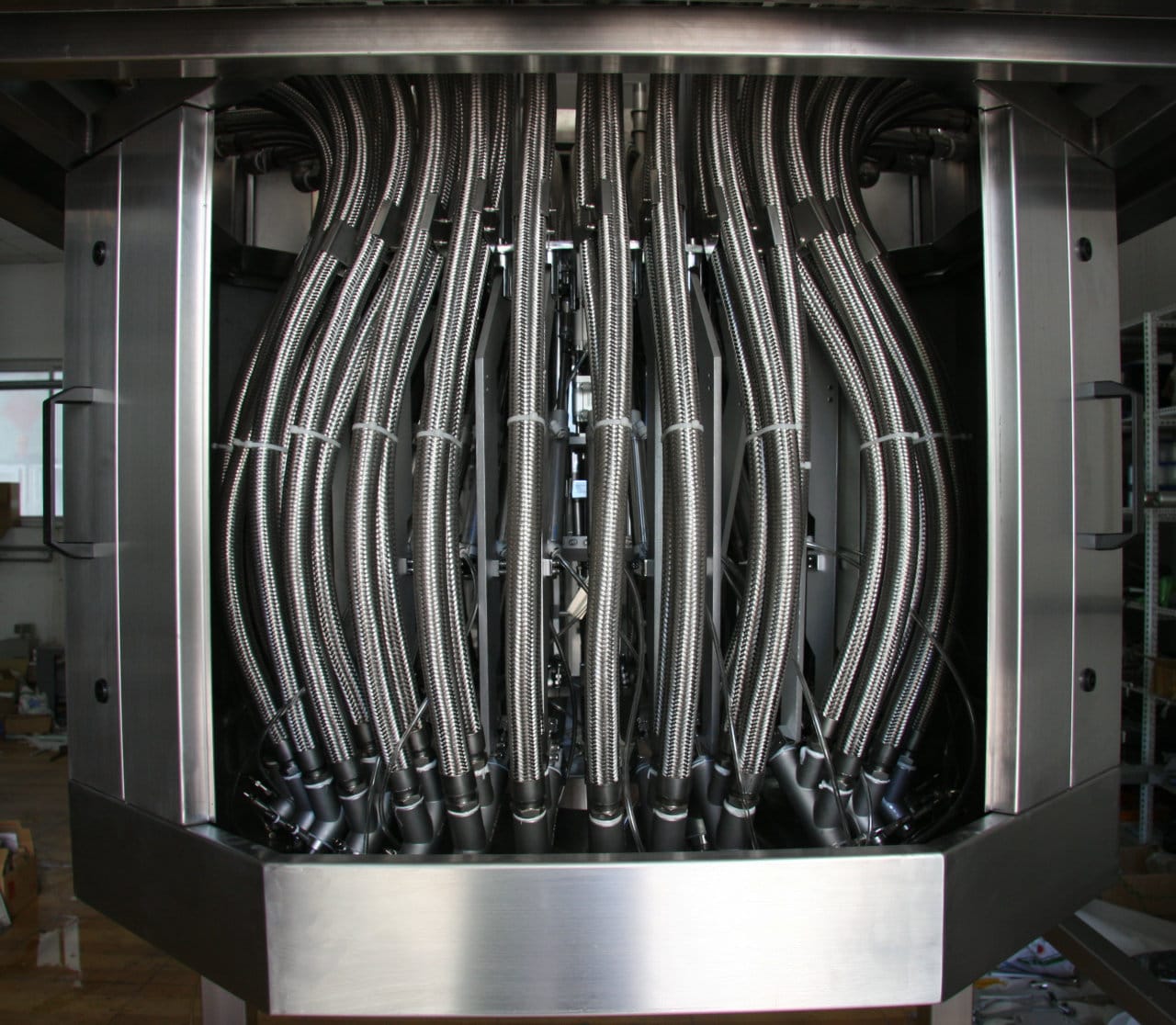

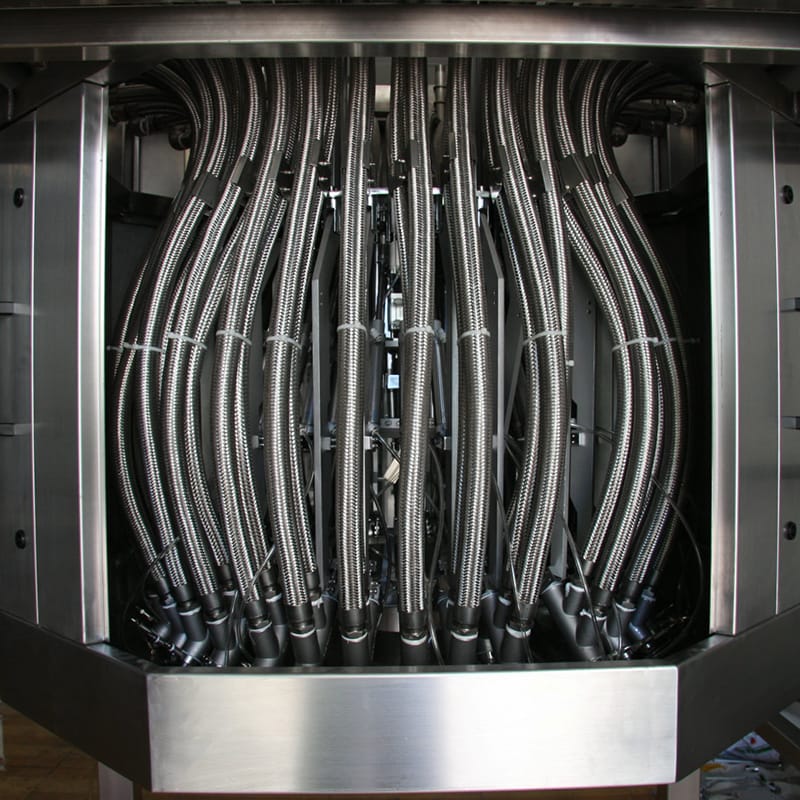

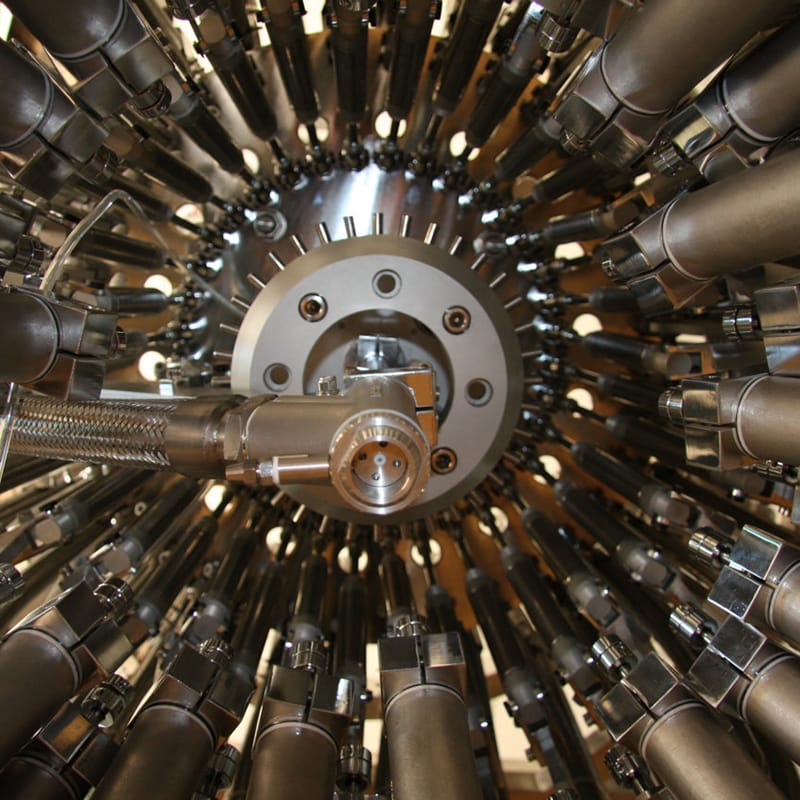

Valves are placed on swing arms or slide guide. When dispensing, the valve is moved to the central position and the flow of the valve is controlled by the opening unit. Valves can be operated at high, medium, low and drip speeds. This dispensing method can ensure that the material is dispensed into a very small container. The method are divided into swing type and push type.

Valve quantity: up to 60

Valve seal: free O-ring

Explosion proof type: Positive pressure explosion-proof

Ex grade: Zone 1 or Zone 2

Valve size: DN20-DN65

Pump size: DN15-DN65

Electronic scale: 7-1500kg

Accuracy: up to 0.1g

Container size: >250mm

Efficiency: 4-5min/20kg 8-10min/200kg 20-30min/1500kg

Diaphragm Pump

Specification: 1”

Models: 666120-344-c

Pump Type: Metallic Air Operated Double Diaphragm

Maximum Air Inlet Pressure: 120 psig (8.3 bar)

Maximum Material Inlet Pressure: 10 psig (0.69 bar)

Maximum Outlet Pressure: 120 psig (8.3 bar)

Maximum Flow Rate (flooded inlet): 35 gpm (133 lpm)

Product detail pictures:

Related Product Guide:

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of Chinese wholesale Pharma Dispensing System - Ink Dispensing System Solvent Single Point Dispenser – Golden Color , The product will supply to all over the world, such as: Rio de Janeiro, United Arab emirates, Namibia, In order to meet our market demands, we have paied more attention to the quality of our products and services. Now we can meet customers' special requirements for special designs. We persistently develop our enterprise spirit "quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.