Automated batching system for leather finishing

The characteristics of leather finishing ingredient system are that there are many kinds of color paste and additives, and many materials are easy to crust, oxidize, some of them are expensive. The manual dispensing workload is large, and it is easy to cause waste of raw materials. The system developed by our company can realize one-stop distribution of color paste and additives. 120 kinds of materials can be allocated and automatically stirred after distribution. During the whole process, color paste and additives are stored in a storage, centralized pipeline transportation, effectively isolating air and preventing material from crusting and oxidation. Customers generally responded that after using the system, the efficiency of batching was improved, the waste of materials was reduced, and the economic benefit was greatly improved.

System parameters:

Distributable Material Quantity: up to 120

Distribution accuracy of color paste: 1g

Type of mixer: automatic cleaning and double-axle mixing

Color paste scale: 150 kg 6550

Additives scale: 300kg + 10g

Automated batching system for Leather Waterworks

The working environment of leather waterworks is poor, the production process of drum is complex and there are many processes. Because of the difference of raw materials and the different application fields of products, the process formulation is often adjusted. There are many processes in the whole engineering, each process has the problem of ingredient feeding, and there are strict time requirements. At present, leather products are basically made up of artificial ingredients and feeding materials, and the labor intensity of personnel is very high. According to the technological characteristics and requirements of waterworks, our company designed the automatic batching system of leather waterworks. Material (except formic acid) is distributed by weighing and stored centrally. According to the characteristics of high viscosity of material, it is transported to the weighing station by high-viscosity pump for distribution. After distribution, it is automatically added to the drum. The whole process is automatically controlled, the rhythm calculation is automatically carried out, and the maximum efficiency of distribution is brought into full play. Highly intelligent and automated design reduces man-made deviation and greatly reduces the work intensity of operators; advanced management software combined with customer production process greatly improves the utilization rate of materials, reduces waste, improves the production environment and reduces the labor intensity of producers while improving the economic benefits of enterprises. Reduce pollution and save energy, reflecting good social benefits.

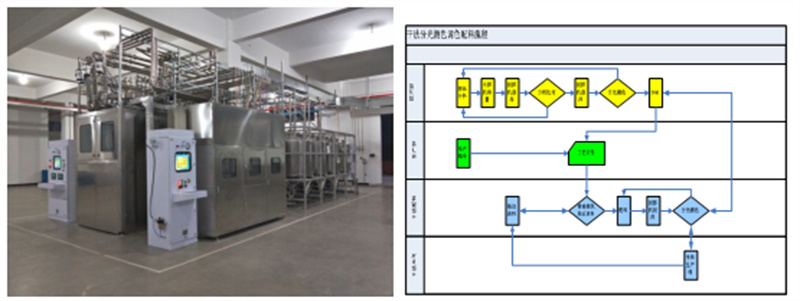

Dry process dispenser for synthetic leather

Traditional color matching process of synthetic leather relies entirely on manual color matching, but due to different light sources and different color discrimination abilities, the accuracy of color matching is poor and the color reproduction is not high. The automatic dry color matching system developed by our company uses computer color matching instead of manual color matching, establishes color database, and generates automatically by spectrophotometer. Formula, computer color matching improves color matching accuracy, saves color paste, reduces residual paste, and reduces production cost. The automatic feeding system can distribute color paste, high viscosity resin and solvent accurately in one stop, which greatly improves the accuracy and efficiency of batching, especially for the distribution of resin with very high viscosity, reduces the dilution link and reduces the labor intensity. The powerful management function of the software can easily realize the functions of recipe inquiry, recipe modification and residual material reuse.